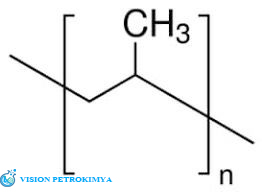

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance.[1]

Bio-PP is the bio-based counterpart of polypropylene (PP).[2][3]

Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion.[4] Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021.[5]

Contents 1 History 2 Chemical and physical properties 2.1 Mechanical properties 2.2 Thermal properties 2.3 Chemical properties 2.3.1 Molecular structure – tacticity 2.3.2 Crystal structure of polypropylene 2.3.2.1 Is polypropylene (PP) 2.3.2.2 Syndiotactic polypropylene (sPP) 2.3.2.3 Atactic polypropylene (aPP) 2.3.3 Copolymers 2.3.4 PP-RCT 2.3.5 Degradation 2.4 Optical properties 3 Production 3.1 Catalysts 4 Manufacturing from polypropylene 4.1 Biaxially oriented polypropylene (BOPP) 5 Applications 5.1 Clothing 5.2 Medical 5.3 Niche 6 Recycling 7 Repairing 8 Health concerns 9 Combustibility 10 References 11 External links

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

50 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

1450 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

26 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

5 |

% |

ASTM D638 |

|

Izod Impact Strength (notched) at 23 °C |

65 |

J/m |

ASTM D256 |

|

Izod Impact Strength (notched) at -20 °C |

45 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

155 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

105 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

EP548T

|

Typical Properties |

Value |

Unit |

Method |

|

|

Physical |

|

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

40 |

g/10min |

ASTM D1238 |

|

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

|

Mechanical |

|

|

|

|

|

Flexural Modulus |

1100 |

MPa |

ASTM D790 |

|

|

Tensile Strength at Yield |

28 |

MPa |

ASTM D638 |

|

|

Tensile Elongation at Yield |

9 |

% |

ASTM D638 |

|

|

Izod Impact Strength (notched) at 23 °C |

55 |

J/m |

ASTM D256 |

|

|

Thermal |

|

|

|

|

|

Vicat softening point (10N) |

128 |

°C |

ASTM D1525 |

|

|

H.D.T. (0.45 MPa) |

82 |

°C |

ASTM D648 |

|

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

|

|

Optical |

|

|

|

|

|

Haze (1 mm) |

11 |

% |

ASTM D1003 |

|

|

Gloss |

90 |

—- |

ASTM D2457 |

|

RP345S

|

Typical Properties |

Value |

Unit |

Method |

|

|

Physical |

|

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

6.0 |

g/10min |

ASTM D1238 |

|

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

|

Mechanical |

|

|

|

|

|

Flexural Modulus |

650 |

MPa |

ASTM D790 |

|

|

Tensile Strength at Yield |

22 |

MPa |

ASTM D638 |

|

|

Tensile Elongation at Yield |

12 |

% |

ASTM D638 |

|

|

Izod Impact Strength (notched) at 23 °C |

80 |

J/m |

ASTM D256 |

|

|

Thermal |

|

|

|

|

|

Melting Temperature (DSC) |

136 |

°C |

ASTM D3417 |

|

|

Vicat softening point (10N) |

118 |

°C |

ASTM D1525 |

|

|

H.D.T. (0.45 MPa) |

65 |

°C |

ASTM D648 |

|

|

Accelerated oven ageing in air at 150 °C |

300 |

hours |

ASTM D3012 |

|

|

Optical |

|

|

|

|

|

Haze (1 mm) |

1.0 |

% |

ASTM D1003 |

|

|

Gloss |

85 |

—- |

ASTM D2543 |

|

RP120L

|

Typical Properties |

Value |

Unit |

Method |

|

|

|

Physical |

|

|

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

6.0 |

g/10min |

ASTM D1238 |

|

|

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

||

|

Mechanical |

|

|

|

|

|

|

Flexural Modulus |

1300 |

MPa |

ASTM D790 |

|

|

|

Tensile Strength at Yield |

25 |

MPa |

ASTM D638 |

|

|

|

Tensile Elongation at Yield |

6 |

% |

ASTM D638 |

|

|

|

Izod Impact Strength(notched)at 23 °C |

200 |

J/m |

ASTM D256 |

|

|

|

Izod Impact Strength(notched)at -20 °C |

60 |

J/m |

ASTM D256 |

|

|

|

Thermal |

|

|

|

|

|

|

Vicat softening point (10N) |

150 |

°C |

ASTM D1525 |

|

|

|

H.D.T. (0.45 MPa) |

90 |

°C |

ASTM D648 |

|

|

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

|

|

EP440L

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

10 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

850 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

18 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

6 |

% |

ASTM D638 |

|

Izod Impact Strength(notched)at 23 °C |

500 |

J/m |

ASTM D256 |

|

Izod Impact Strength(notched)at -20 °C |

100 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

135 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

75 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

EP3130UV

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

21 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

1500 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

26 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

6 |

% |

ASTM D638 |

|

Izod Impact Strength(notched)at 23 °C |

90 |

J/m |

ASTM D256 |

|

Izod Impact Strength(notched)at -20 °C |

40 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

150 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

110 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

EP548R

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

6.0 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

1400 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

32 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

8 |

% |

ASTM D638 |

|

Izod Impact Strength (notched) at 23 °C |

40 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

152 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

84 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

HP552R

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

42 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

1400 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

32 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

8 |

% |

ASTM D638 |

|

Izod Impact Strength (notched) at 23 °C |

30 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

152 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

84 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

150 |

hours |

ASTM D3012 |

HP564S

|

Typical Properties |

Value |

Unit |

Method |

|

|

Physical |

|

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

1.3 |

g/10min |

ASTM D1238 |

|

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

|

Mechanical |

|

|

|

|

|

Flexural Modulus |

1300 |

MPa |

ASTM D790 |

|

|

Tensile Strength at Yield |

25 |

MPa |

ASTM D638 |

|

|

Tensile Elongation at Yield |

6 |

% |

ASTM D638 |

|

|

Izod Impact Strength(notched) at 23 °C |

500 |

J/m |

ASTM D256 |

|

|

Izod Impact Strength(notched)at -20 °C |

70 |

J/m |

ASTM D256 |

|

|

Thermal |

|

|

|

|

|

Vicat softening point (10N) |

150 |

°C |

ASTM D1525 |

|

|

H.D.T. (0.45 MPa) |

92 |

°C |

ASTM D648 |

|

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

|

EP440G

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

3.0 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

1400 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

32 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

9 |

% |

ASTM D638 |

|

Izod Impact Strength(notched)at 23 °C |

55 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

152 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

84 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

500 |

hours |

ASTM D3012 |

|

Optical |

|

|

|

|

Haze (20μm) |

0.5 |

% |

ASTM D1003 |

HP525J

|

Typical Properties |

Value |

Unit |

Method |

|

Physical |

|

|

|

|

Melt Flow Rate (230 °C, 2.1 6kg) |

3.2 |

g/10min |

ASTM D1238 |

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

Mechanical |

|

|

|

|

Flexural Modulus |

1400 |

MPa |

ASTM D790 |

|

Tensile Strength at Yield |

32 |

MPa |

ASTM D638 |

|

Tensile Elongation at Yield |

9 |

% |

ASTM D638 |

|

Izod Impact Strength (notched) at 23 °C |

50 |

J/m |

ASTM D256 |

|

Thermal |

|

|

|

|

Vicat softening point (10N) |

152 |

°C |

ASTM D1525 |

|

H.D.T. (0.45 MPa) |

84 |

°C |

ASTM D648 |

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

HP550J

|

Typical Properties |

Value |

Unit |

Method |

|

|

Physical |

|

|

|

|

|

Melt Flow Rate (230 °C, 2.16 kg) |

6.0 |

g/10min |

ASTM D1238 |

|

|

Density |

0.9 |

g/cm3 |

ASTM D1505 |

|

|

Mechanical |

|

|

|

|

|

Flexural Modulus |

1400 |

MPa |

ASTM D790 |

|

|

Tensile Strength at Yield |

32 |

MPa |

ASTM D638 |

|

|

Tensile Elongation at Yield |

8 |

% |

ASTM D638 |

|

|

Izod Impact Strength (notched) at 23 °C |

40 |

J/m |

ASTM D256 |

|

|

Thermal |

|

|

|

|

|

Vicat softening point (10N) |

152 |

°C |

ASTM D1525 |

|

|

H.D.T. (0.45 MPa) |

84 |

°C |

ASTM D648 |

|

|

Accelerated oven ageing in air at 150 °C |

360 |

hours |

ASTM D3012 |

|

HP510L