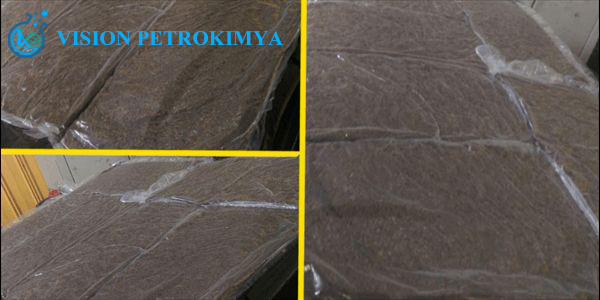

SBR-1723 TDAE Synthetic styrene-butadiene rubber Oil-extended styrene butadiene synthetic rubber SBR-1723 TDAE is a styrene (23.5%) and butadiene (76.5%) copolymer obtained by emulsification method with the usage of resin and fatty soaps. The copolymer is filled with oil TDAE and stabilized with staining antioxidant. Appearance: bale of dark-brown color; weight of a bale — 30 ± 1 kg Package: PE wrapping film (Vicat softening point ?95 °C); metal and plywood containers (1.26 MT) or plastic container 0,54 MT Shelf life: 2 (two) years from the date of manufacture Parameters Mooney viscosity MML 1+4 (100 °C), UM Organic acids, % wt Organic acids soap, % wt Bound styrene, % wt Solvent extract, % wt Oil, % wt Volatile matter, % wt Ash, % wt Storage conditions: at the temperature not higher than 30 °C, in place protected from direct sunlight and atmospheric precipitation SBR-1723 TDAE grade B 46–54 4,0–5,6 ?0,30 22,0–25,0 29–35 25,0–30,0 ?0,6 ?0,6 Test method ASTM D 1646 ASTM D 5774 ASTM D 5774 method of supplier method of supplier ASTM D 5774 ASTM D 5668 ASTM D 5667 ASTM D 412 Stress-strain properties in standard recipe on ASTM D 3185 (method 1A), 145 °C x 35 min. Tensile stress at 300 % elongation, MPa ?9,8 Tensile strength, MPa ?18,0 Ultimate elongation, % ?380 Curing characteristics of rubber compound: Rheometer MDR 2000, measurement conditions: 160 °C, deformation of 0.5°, MH at 30 min. Minimum torque (ML), dNm Maximum torque (MH), dNm Scorch time (ts ?1), min. Time to 50 % of full cure (t ?50), min. Time to 90 % of full cure (t ?90), min. Technical support service: techservice@sibur.ru 1,4–3,0 12,0–18,5 3,2–6,5 6,5–10,5 12,0–18,5 ASTM D 5289