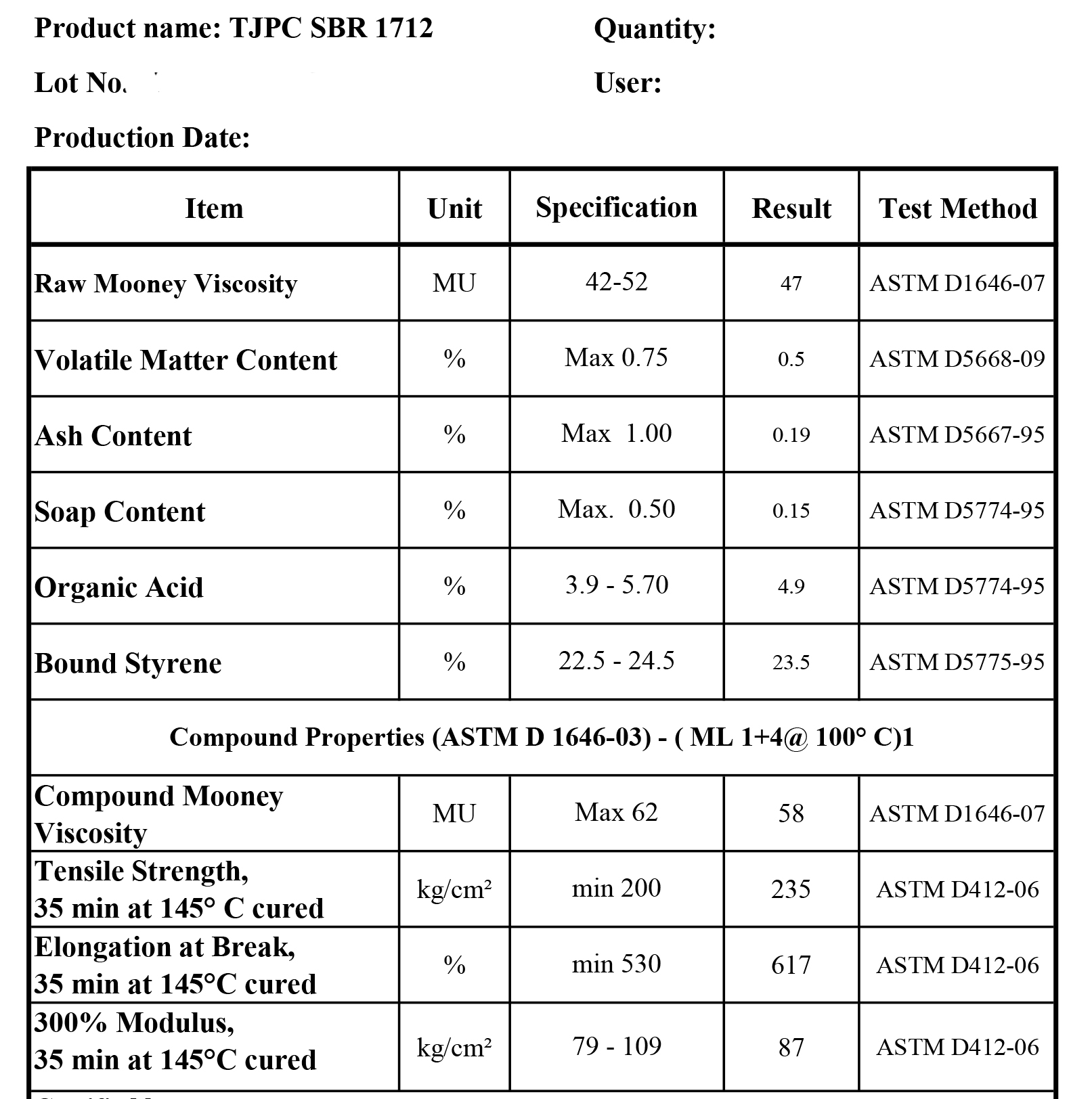

1)Description: SBR–1712 STYRENE BUTADIENE RUBBER SBR–1712 is staining type cold SBR ,extended with 27.5 part of highly aromatic oil. Provided that the compounds are formulated and processed correctly ,the vulcanized SBR–1712 has very good abrasion ,good electrical properties and good resistance to polar solvents and dilute acids. 2) Applications: The SBR-1712 used for the production of tires, high quality technical rubber goods,moulded and extruded mechanical rubber goods and other industrial products where colour and staining are not decisive factors. 3) Typical data Volatile matter Ash Organic acid Soap Oil content Bound styrene Raw viscosity (ML 1+4 @ 100 oC) Compound viscosity (ML 1+4 @ 100 oC) Tensile strength Ultimate elongation 300 % Modulus Property Unit wt% wt % wt% wt % wt % wt% – – kg/cm2 % kg/cm2 Value 0.75 max 1.5 max 3.9-5.7 0.5 max 25.5-28.5 22.5-24.5 42-52 62 max 200 min 530 min 79-109 Test Method ASTM D 1416 ASTM D 1416 ASTM D 1416 ASTM D 1416 ASTM D 1416 ASTM D 1416 ASTM D 1646 ASTM D 1646 ASTM D 412 ASTM D 412 ASTM D 412 The above data are typical laboratory average . They are intended to serve as guides only. SBR–1712 STYRENE BUTADIENE RUBBER Compounding formula :(ASTM D–3182 & D–3185): SBR Chemical: Carbon black IRB = 6. Conforming to NBIS – SRM No. 378 Zincoxide: NBS – SRM No. 370 Stearic acid: NBS – SRM No. 372 Sulfur: NBS – SRM No. 371 Accelerator (TBBS): NBS – SRM No.384 Temperature: 145 oC Cure time: 35 min 412.5 (gr) 206.25 (gr) 9.0 (gr) 3.0 (gr) 5.25 (gr) 4.14 (gr)